|

|

|

|

#1

|

||||

|

||||

|

Anything new with this?

|

|

#2

|

||||

|

||||

|

I have progressed somewhat with the top restoration, but have been overseas for six weeks and so everything ground to a halt. Will resume work on the bass soon and post more pics.

|

|

#3

|

||||

|

||||

|

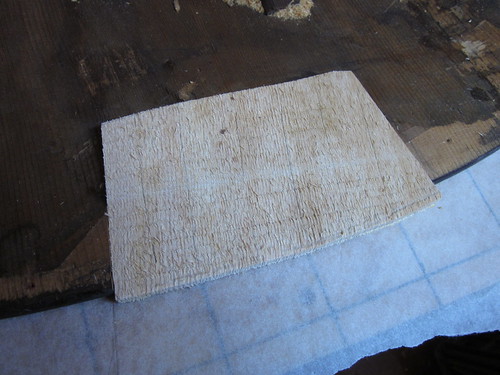

You can see how worn the corners were here:

After gluing most of the belly cracks (I found a few more) I had a go at repairing the corners with my usual repair wood but i wasn't happy with the result, as the grain really didn't match. The grain on this bass top is wide at the flanks, and wavy. So I tried using the reed-by-reed technique i posted a link to a week ago. I cut away a part of the damaged wood along the grain line, then glued in a single piece of wide grain spruce. Then trimmed it back, and then added another.     I'm working from the back here but i check the front to make sure the grain lines are reasonably straight. They will be covered in a dark varnish, but with purfling repaired they will look much better. I addition, these corners - and a lot of the edges - will get a half-edging repair. so what you see above will be covered with perhaps 2-3mm of tighter grained spruce, which will be better for gluing to the blocks! Last edited by Matthew Tucker; 09-03-2010 at 07:39 PM. |

|

#4

|

||||

|

||||

|

As it happens ... in case anyone likes to watch.

This is a previous repair to the block area of the lower bout  However, cracks have developed along one side and i don't like the previous repair or the nail holes so I'm removing the old repair and replacing with new wood.  I've removed all but the last 2mm of the top wood and tapered the edges inwards so that the patch fits tightly and the repair edge doesn't align with any grain. I've lost a bit of the very brittle purfling near the saddle but this was falling away anyway.  That's the patch glued in. Still has to be planed flat. There was a similar problem up the top end. 2" nails through the top had made a nasty mess and a fair bit of wood had come away when removing the top from the block. And a previous repair. You can see my first exploratory gouge to see whether I could do an inlay patch, but nup. Had to go further to make sure the repair was sound.  I had to remove only enough spruce till I got to reasonably sound wood. I filled the nail holes with sawdust and hide glue from the back; i'll do a better repair from the front, later.  here's the patch glued in, waiting to be trimmed back.  |

|

#5

|

||||

|

||||

|

This is what nails do to the edge! I've planed back the crumbly chipped edge back to clean wood.

closer, you can see what this spruce is like. Wavy, wide-grained, with a few brittle knotty bits at the flanks like this  or this bit of repeated trauma which has pulverised the spruce under the varnish. I have to plane back as far as i dare then do the rest with glue and new spruce edging.  This new spruce is much nicer to deal with and will properly strengthen the original edges. It will glue better, too.  |

|

#6

|

||||

|

||||

|

Looking good Matt. On those Block area inlays, did you considered a feathered-in patch like a breast patch type (and inner half edging) so as not to create another fault line in the process? There is considerable pressure on the Top at the block areas. Anything that can be done to avoid future trouble would be good. Just like saddle cracks. A tight patch in there like you've shown might act differently than a feathered-in type repair.

|

|

#7

|

||||

|

||||

|

You're right, and I did consider it, but in the end I decided that angling the ends inwards as i have done will also spread the stress across a number of grains, much less likely to cause a fault crack as on the Right Hand Side of the picture below. Also the grain of the patch is very slightly offset so it doesn't run parallel with the top grain. Feathering the edges is quite a bit more work.

in fact you can see in the original repair, the left hand edge is still quite sound; it is angled. The right-hand edge however is parallel to the grain of the top and right alongside the saddle cutout - recipe for a weak point and a classic saddle crack, which is in fact what happened. Last edited by Matthew Tucker; 09-03-2010 at 07:32 PM. |

|

#8

|

|||

|

|||

|

Quote:

|

|

#9

|

||||

|

||||

|

Well, this hunk of timber needs to be replaced. It's going to be a time consuming and messy job pulling it out without damaging anything. I'm going to try to steam it all apart but if this gets too tricky I'll probably end up cutting it out.

I found a bit more of the original varnish under a lot of dirt; it gives me the original colour, but there's no chance of recovering any of it on the ribs.  found some more metalwork holding the ribs on. Glad I found these before my blades did.  And yet MORE Metalwork ...  This is the wonderful screw I'm going to keep as a trophy! Pretty amazing that another hole was drilled right through the shank for the bolt that I originally extracted from the back of the button!  Loosening the neck block at the back seam. Look at all that stickiness:  Previous button repair came away. Some of it has been repaired with spruce, and there's a fair whack of putty in there too. I'm going to have to restore the whole button from scratch.  I got the old neck heel out sans trop de dégâts. The tear you can see on the right is the old spruce block that will be replaced entirely. Look at that lovely crack, subject to so much metalwork and dowelling in its lifetime!   |

|

| Currently Active Users Viewing This Thread: 23 (0 members and 23 guests) | |

| Thread Tools | |

| Display Modes | |

|

|