|

|

#61

|

||||

|

||||

|

Quote:

|

|

#62

|

|||

|

|||

|

Quote:

|

|

#63

|

||||

|

||||

|

On the subject of "dangerous" bass bars -

If, as in this case, a grain-parallel bar has yet to encourage a crack, is there really much justification for assuming that it will in the future, left as is? I mean sure, it makes sense to place a new bar across the grain, but I'm not seeing a real reason to replace an otherwise sound bar for this reason. |

|

#64

|

||||

|

||||

|

Well if the top is overly thick under the bar, and/or the bar is overly heavy and stiff, then you will get a strong top a that spot, no matter what orientation the grain. But this is not necessarily a recipe for a responsive top and optimum sound. Also, this top was NOT intact - as you can see from the earlier pics it was seriously cracked in at least a dozen places; perhaps if the top was more flexible (thickness, arching shape, bar shape) it would not have cracked in that way. Perhaps the strength of the top around the bar itself encouraged cracks to form elsewhere? Perhaps, perhaps not ... who knows? All I know for sure is that the top is quite a bit heavier and less flexible than usual, and the bass bar is also very hefty and stiff. The original bar is intact, sure, but there's no evidence that it is "otherwise sound" if you measure that by how well it performs. So its a matter of using intuition to decide how to achieve the right balance of flex and strength.

@wayne - I think if you are making a plaster mould for each top you work on you must have a very big workshop and be built like a lumberjack! I've never needed to make a full top plaster mould - i'd be interested to see some pics of your setup. I just have the top sitting in an MDF cutout cradle with no sharp edges and clamped in various ways. I don't use any protection on the top either, the MDF is softer than the wood and varnish, but if I feel the top needs any special support I'll use a smallish sandbag underneath. I'd really hesitate to use any kind of tape on the finish - even painter's tape - imagine the feeling you'd get if the solvents in the adhesive reacted with the varnish and the finish came off with the tape  No thanks. No thanks.Last edited by Matthew Tucker; 09-12-2010 at 08:44 PM. |

|

#65

|

||||

|

||||

|

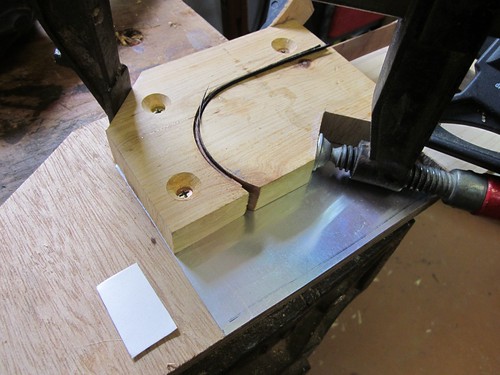

On the weekend I bit the bullet and decided, after a chat with the owner, to remove the bass bar. I had some assistance from my nephew Luke who has helped me on some of my other builds.

We managed to recuperate some of the original bar to use as repair wood as the timber matches the top in colour and grain width.  After removal the top weighs 1665g.` |

|

#66

|

||||

|

||||

|

While this was going on I started on making some purfling for the corner repairs.

I discovered that the original purfling is made of a pinkish wood, not white. I'm guessing this is some kind of fruit wood like pear or cherry, but not sure what. It's quite hard. I wonder if ID-ing this might help narrow down the bass's origin? I had to hunt through my pile to find something that might match.  The strips are planed down with my large smoother  then taken down to the final thickness with my new HNT Gordon smoother with the blade setup as a scraper.   I have made a special jig for bending the purfling to roughly the right shape. sort of a mini fox-bender. I use a heat-gun for heat.  I've tried both PVA and hide glue; in the end, for this pre-bent stuff, the hide glue worked better.   After the glue is dry I cut the bent laminate into strips  neat, huh? |

|

#67

|

||||

|

||||

|

Nice jig.

Do you heat the strips first and then put them in, or apply heat while bending? It looks like they're dry, right? |

|

#68

|

||||

|

||||

|

Stick 'em in the jig, heat with the gun and bend when hot. This gets them roughly bent. Then i take 'em out of the jig, slop on the glue, add a strip of non-stick "cooking paper" and clamp the lot in the jig until the glue sets.

|

|

#69

|

||||

|

||||

|

Not much to report this weekend, except that the top is now 1663g after removal of the bass bar. The bar was therefore 245g.

I did some more hocus pocus chladni measurements on the top because I can. Have a look at this video (unfortunately we can't embed video on this site yet) to see how the first mode looks in stop-motion! http://www.youtube.com/watch?v=aHbpC_0E7wM     Last edited by Matthew Tucker; 09-26-2010 at 01:44 AM. |

|

#70

|

|||

|

|||

|

Out of ignorant curiosity, what does vibrating the top with sand in it tell you? You have my interest very piqued, and I really appreciate all the pictures and updates in this thread. I love seeing all the details and effort that go into this. Kudos.

|

|

#71

|

||||

|

||||

|

it just tells me the frequency of the resonant modes of that top. Combined with the weight, it can give a numerical value for stiffness. Sometimes it can reveal asymmetries in stiffness. But it tells me no more about the tone of the bass than other measurements such as the width of the plates. For the moment it is just another measurement to keep track of and compare with other basses, but its fun to do and looks cool.

|

|

#72

|

|||

|

|||

|

It does look cool, that is for sure. So, ideally, would all the sand be symmetrical? I see that it mostly is, except at one frequency were there is a slight variance. It is pretty incredible the different patterns it forms based on frequency of vibration. How consistent are the results? If you were to do the same test back to back, are the results identical?

Sorry for all the questions, just very curious. |

|

#73

|

||||

|

||||

|

yes same tests back to back are identical if nothing else changes. I suppose if you take the view that symmetrical plates are ideal or necessary (although there's no evidence that this is the case) then symmetrical shapes would indicate this.

My ideal is to get the tea-leaf patterns looking as much like Yosemite Sam as possible. Yosemite Sam is the holy grail of chladni enthusiasts ... I have a long way to go. |

|

#74

|

||||

|

||||

|

Quote:

Doesn't that top need some cleats for all the cracks you glued up so far? How will Sam react to that? Have fun.. |

|

#75

|

||||

|

||||

|

Yosemite Sam is just me being silly, Ken. For me it is JUST another measure of the top and doesn't really give any more clues about what must be done than does the distance between the FFs or the size of the endpin block or the width of the lower bout. Since I have the bass top off I can make these measurements and see what happens when i remove wood where I think it needs to be removed. I'll also be able to compare what happens when I cleat the cracks, and when I add the new bass bar.

The patterns are cool but are only a flag to show that the particular resonance mode has been met. I don't know enough about the shape to be able to draw any conclusions. And there are too many variables ... such as the arching shape for starters. The most interesting number I think is the frequency of vibration which combined with the weight of the plate is a measure of stiffness. If, after I do everything and re-cleat and replace the bass bar, the modes appear at the same frequencies, I can - I think - assume that the plate is fairly consistent with how it started out. If on the other hand, the frequencies are lower, but the weight is the same, this will show me that what I have done has increased the flexibility of the plate. I can make those sorts of observations. I could - and will - also flex the plates with my fingers, tap them etc - and you DO get a lot of tactile feedback when you are working on the plates with the planes and scrapers. But this is more subjective. Nothing here, unfortunately, will tell me whether I've done enough ... or gone too far! See where I'm coming from? I'm not looking for a magic pill; it would be nice in a way if we could ****yse this work scientifically but I don't think this is at all easy - at the end of the day a luthier's work a series of educated hunches and generalisations. Some people might think that this sort of mucking around is a waste of time but for me, the more information I have to inform my instincts, the better. |

|

#76

|

||||

|

||||

|

I wonder if there is a comparable system for testing resonance of a plate on a complete instrument. Seems like testing the plate on its own, then as part of the complete assembly, and finally under tension would give a lot of insight that could be applied not only that instrument but to making new ones and improving older ones.

|

|

#77

|

|||

|

|||

|

So... Is the plan to re graduate, then put the bass bar and cleats back in? Or is it a combination of installing and graduating as you go?

Also... how do you keep from losing your crack locations? |

|

#78

|

||||

|

||||

|

Quote:

I think he said further up the thread that he uses a grease pencil or something to mark out the cracks... |

|

#79

|

||||

|

||||

|

The procedure is to get the top thicknesses right first, then add the bass bar and cleats. It's much easier to track the cracks now that the surface is mostly clean wood.

Thomas here are SOOO many variables I really don't think anyone could live long enough to repeat what Carleen Hutchins did in her lifetime and come up with something new. I think that measuring the resonance of a free plate is a completely different thing to measuring an assembled instrument - no comparisons can be made because they are two different things. It would not be hard to measure an assembled instrument I suppose, but then it would be very complicated to make any adjustments. I'm not about to go there! |

|

#80

|

|||

|

|||

|

Any progress? I've really been fascinated by this project.

|

|

| Currently Active Users Viewing This Thread: 53 (0 members and 53 guests) | |

| Thread Tools | |

| Display Modes | |

|

|